Welcome to the Forum!

NICE, we love pictures of all minis, but I especially LOVE the spots. We haven't started our black and white colt in harness yet... Eventually, we will.

I can't post pics directly here anymore, but I have posted some links below each part -

Shelters - we now use the cattle panels for our chicken coops - partially because we were expecting to move them (not the easiest task) and partially because they were supposed to be temporary. Well, they've become somewhat permanent and work great! They are 8' wide at the base, the panels are 16' long and arched they are more than 5 - 1/2" tall (I can stand easily under them). I use two 50" panels that are joined edge to edge w/ no overlapping - so the "coop" is 100" long or a little over 8' long. I have purchased mostly the inexpensive tarps and because our barn cats climb on them, they shred and need to be replaced about every 12 months or so. I have had donated tarps and also expensive ones purchased used, at a lower cost.

chicken coop 1 -

chicken coop 1 front

I also use the cattle panels in combo with pallets for sheds that house feed, hay and tools. In a pinch, we've groomed our Shetland ponies in them and trimmed hooves - though it would be better for the sheds to be larger for that type of activity.

This shed was a real temporary solution when we moved our ponies from property we'd leased for 10 years to a temporary set up for almost 3 full months. The pallets are an "odd size" of 48"x48", so I was able to get them for $2/each. I know that it is 8' deep & wider than 8' but never measured so don't know exact width. It's tall enough for me to stand up in. The 2 panels for the roof are not new. The whole set up is strapped together with hay string...

shed1 - a,

shed1 - b,

shed1 - c

We liked it so well that I put two together on our new property. Eventually they will be bolted together and the panels joined by more than hay string. Thought I'd do some different things for roofs, but haven't gotten that far - just use them as they are!

shed2 - a,

shed2 - b

This shed is a measured 8x12 and is getting ready to be expanded to 12x16. I did put steel posts in the ground and dropped the pallets down over them to hold them in place better in the front only. There are a lot of different ways you could do a gate or a door - I used what I had, LOL. Shed 2 and shed 3 have now been in constant use for a little over 2 full years - w/ just haystring holding them together. They've withstood the torrential rains & winds of Hurricane Matthew & several other storms that really should have been named plus 4 severe ice episodes - 2 in 2015, 1 in 2016 and 1 in 2017 (shed 2, by the boys' pasture, did have it's tarp roof shredded and also some shift to the walls, but not bad considering it isn't bolted together or on a foundation).

shed3 - a,

shed3 - b

Before trying different bits on your little fellow, have his teeth looked at. If it's been over a year since he's been worked, it may have been at least that long since his teeth were done. A lot of horses do just fine with a straight bar or mullen mouth bit... Then follow what everyone else has stated to do. Here in NC, we now have two HUGE used tack sales every year in Raleigh. Selling tack, bits & pieces and some of our 3 daughters's used show clothes (most of which we purchased used), we made over $800 in 3 years. I also purchased many, many items at this sale and it gets bigger every year!

I have, on occasion, found horsey equipment by posting ISO ads in our local feed stores AND in the TSC's. Of course it helps that I have so many of those w/i 100 miles of us, LOL. I will carry post cards and our business cards w/ me any time I go somewhere new and post either items wanted, items for sale or just our pony farm card at new stores. I have gotten many things that way. Check with a local mini horse show club - drivers may be willing to loan out bits until you find what works for you - or may have them to sell.

Last, but not least, I have made a few bits using 1 - 2" steel rings purchased at a hardware store - but these are essentially straight bar bits as well - just bendable/soft.

Most mini horse catalogs have some different style bits for much less than the $100 you quoted... English tack stores will also carry pony sized bits that may work for you as well (though some of those are going to be "pricey" just by virtue of being from an "english" store).

Julie, who has been a part of this board, built a "stock rack" and carried it in her 1/2 ton truck. At one point, I thought that she had pictures, but I don't know where they are now.

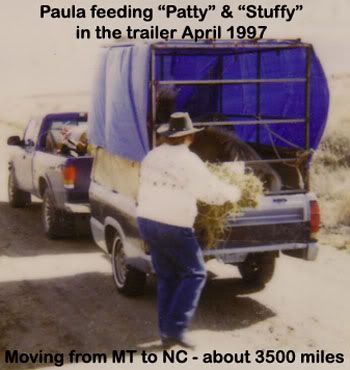

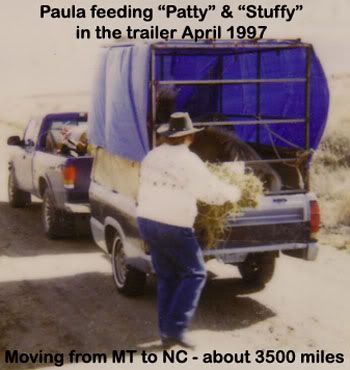

I had (still have it but it's currently not being used) a "stock rack" built for a Ford Courier truck bed (have no idea how old the truck bed was at the time) for a couple hundred $$ (in 1997 - don't know what it would cost to do now). I don't really recommend hauling this way w/ a single axle - my hair stands up just thinking about how many ways this could have gone so wrong. The guy who built it put steel plates on the top of the bed of the truck which the "legs" of the rack sit in. The "top" consist of 3 "u" bars that can be pulled out of the tubes they are sitting in. The whole back (above the tail gate of the truck) will swing open and can be unpinned and completely removed as well. That is a 1/4 ton Mazda B4000 4x4 pulling it. We used it for more than 15 years here in NC w/ the Mazda, a Chevy Trailblazer (small/mini SUV) & our Ford Ranger (also a 1/4 ton) - mostly to haul feed, equipment and trash. It is too small and doesn't sit level if you hitch it to a larger truck, van or full size SUV. Right now the bottom (floor) is completely rusted out and we haven't been able to justify the cost of having it repaired - yet the axle and wheel rims are in good shape... Different photo album - here is probably the only pic I have of it -